Decanter Centrifuge Parts & Service – US Filter, Siemens, Hiller

At Langley Separation & Process we know many of the previous US Filter J-Spin, Siemens and Hiller decanter centrifuge customers, and how important maintaining the mechanical reliability and operational availability of their machines is to them. Given our many years of experience working with the various model US Filter J-Spin, Siemens CentraMax, Siemens CentraPac and Hiller DR decanter centrifuges, Langley Separation and Process is now offering these customers a responsive American based alternative for acquiring parts and service to keep their decanter centrifuges running.

As a factory supported OEM parts and service supplier for US Filter J-Spin, Siemens CentraMax, Siemens CentraPac and Hiller DR decanter centrifuges, Langley Separation and Process has the knowledge and capability to source spare parts and provide both field service and in-shop rebuilds.

Langley Separation Specializes in the parts, field service, equipment repairs, refurbishments, training and onsite equipment and process evaluations for the following decanter centrifuges brands:

US Filter J-Spin Decanter Centrifuge Models:

- CD26-432

- CD31-432

- CD37-432

- CD45-432

- CD51-432

- CD54-432

- CD58-432

- CD66-432

- CD76-402

Siemens CentraMax Decanter Centrifuge Models:

- CD26-432

- CD31-432

- CD37-432

- CD45-432

- CD51-432

- CD54-432

- CD58-432

- CD66-432

- CD76-402

Siemens CentraPac Decanter Centrifuge Package System Models:

- CP26-432

- CP31-432

- CP37-432

- CP45-432

- CP51-432

- CP54-432

- CP58-432

- CP66-432

- CP76

Hiller DR Model Decanter Centrifuge Models:

- DR26-432

- DR31-432

- DR37-432

- DR45-432

- DR51-432

- DR54-432

- DR58-432

- DR66-432

- DR76-402

The center point for Langley Separation activities is Company President and Owner, Mr. Tony Langley. Tony’s 30 years of experience and knowledge in the water, wastewater, and industrial sectors speaks for itself. His impressive resume consists of well-known and competitive companies such as Andritz, Ashbrook and Siemens. In Tony’s own words: “Starting Langley Separation & Process was a big step and our simple mission is to provide customers extraordinary products and services. I also saw where many of my previous customers who still operate US Filter J-Spin, Siemens CentraMax, Siemens CentraPac and Hiller DR decanter centrifuges were no longer being serviced and so I decided to help. The team at Langley Separation knows those machines and we have all the necessary information and resources to provide customers the parts and service they require.”

Whatever your needs our professional staff will reliably answer your technical questions and help troubleshoot your specific requirements, schedule parts shipments and/or arrange for on-site service.

- Mechanical

- Electrical

- Process

Langley Separation has the resources to support your service requirements:

- Qualified and experienced service personnel available

- Fast delivery of spare parts

- Standard and customized maintenance contracts

- First class repair service at our approved regional service centers

Approved Service & Rebuild Centers:

- Van Wert, Ohio

- Houston, Texas

- Bakersfield, California

Decanter Centrifuge Parts and Service

Langley Separation can supply original new OEM replacement parts for all US Filter J-Spin, Siemens CentraMax, Siemens CentraPac and Hiller DR decanter centrifuges and ancillary equipment including bearings, seals, gaskets, and many other consumable wear parts such as feed nozzles and discharge bushings. We can also recondition and repair many worn and / or damaged parts restoring them back to OEM specifications. And if parts have become unavailable or obsolete, we will reverse engineer and manufacture new replacements.

Highly qualified service personnel

The experienced team at Langley Separation will provide process optimization, trouble shooting and field service for US Filter J-Spin, Siemens CentraMax, Siemens CentraPac and Hiller DR decanter centrifuges. We can also provide maintenance contracts designed for the unique requirements of each customer to optimize the reliability and considerably extend the life of your machine. Plus, Langley Separation has an established network of factory approved independent regional repair shops which serve as a supplemental alternative for long term equipment maintenance and repair.

Maintenance contracts

As a convenience to US Filter J-Spin, Siemens CentraMax, Siemens CentraPac and Hiller DR decanter centrifuge customers, Langley Separation offers annual field service contracts with authorized Service Technicians. In addition, Langley Separation and Process will coordinate the complete time and service interval management as well as the corresponding inspection logbook entries providing customers optimum machine reliability and legal security.

Electrical system and operating program trouble shooting

Langley Separation will also provide experienced electrical troubleshooting field services for US Filter J-Spin, Siemens CentraMax, Siemens CentraPac and Hiller DR decanter centrifuges as well as process optimization.

Note: Langley Separation maintains the control system passwords and has access to the programs for most of the machines presently installed.

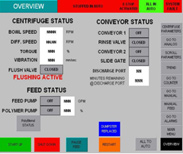

Process automation and centrifuge control panel

Langley Separation can provide process control solutions and upgrades to increase centrifuge and system performance. We can help you increase production and profits with state-of-the-art electronic controls, hydraulic drives and AC variable speed drive systems. Whether it’s a panel for a new machine or upgrade of an older machine, all aspects of automation and process controls are managed from design, engineering and construction through installation, integration and start-up.

- Allen Bradley, Siemens and other Programmable Logic Controllers (PLC)

- VFD drives, variable frequency, network interface and communications

- Operator Interface Terminals (OIT) and Human-Machine Interfaces (HMI)

- Data acquisition and trend analysis

- UL508A and NFPA approved industrial control panels

- Custom automation and process control optimization

- Complete centrifuge control and automation of all functions and ancillary equipment

- Complete dewatering system automation

Decanter Centrifuge Repair Services

Langley Separation also provides US Filter J-Spin, Siemens CentraMax, Siemens CentraPac and Hiller DR decanter centrifuge decanter centrifuge rotating assembly, rebuild, repair, refurbishing and complete reconditioning services. Field and/or in-shop rebuild services are designed to restore your dewatering equipment back to its original performance levels.

Standard rebuild and repair services include:

- Scroll / conveyor inspection including feed zone and flighting repair as well as re-hard surfacing and re-tipping with flame sprayed wear protection and / or replacement of sintered tungsten feed port inserts and carbide scroll tiles

- Re-balancing scroll / conveyor

- Back-drive gearbox repairs

- Hydraulic back-drive repairs

First Class Decanter Centrifuge Refurbishing

Rebuilding your US Filter J-Spin, Siemens CentraMax, Siemens CentraPac and Hiller DR decanter centrifuge decanter equipment is more often a cost-effective alternative to complete replacement and Langley Separation will work within your budget. These services often include the following steps depending on machine condition at the time of service as well as selected features to optimize your system with the latest technological improvements.

- Complete disassembly of decanter centrifuge

- Cleaning of all parts and components

- When necessary verify materials of construction using X-Ray Metallurgist Pro instrument

- Crack check key parts with Zyglo® liquid fluorescent penetrant inspection (Magna Flux)

- Media-blast all structural items and product contact surfaces

- Measurement of all critical tolerances and bearing fits

- Repair major sub-standard parts utilizing factory OEM prints and support

- Replace major consumable and / or sub-standard parts with new OEM parts

- Installation of complete head wall and scroll bearing seal assemblies

- Two-plane dynamic balancing of rotating assembly as required

- Scroll / conveyor inspection including feed zone and flighting repair as well as re-hard surfacing and re-tipping with flame sprayed wear protection or replacement of sintered tungsten carbide tiles

- Re-balance scroll / conveyor

- Repair and squaring of bearing pillow block mounting base locations

- Installation of rotating assembly

- Repair and refurbishment of covers and casings

- Perform four-hour operational test-run of completed centrifuge repairs

- Verify and record dynamic balance

- Paint required items (customer to specify paint type & color)

- Re-skidded for shipment

US Filter J-Spin, Siemens CentraMax, Siemens CentraPac Machine History Reference

The complete range of US Filter J-Spin, Siemens CentraMax, Siemens CentraPac decanter centrifuges were originally contract manufactured for US Filter and Siemens by Hiller in Germany. Hiller also produced private label decanter centrifuges for KHD Humboldt and Bird. Langley Separation can provide OEM factory supported service and spare parts for North American customers operating KHD, KHD Humboldt, HDI (Humboldt Decanter Inc.), Bird, Baker Process, Siemens CentraMax and CentraPac / US Filter J-Spin branded decanter centrifuge equipment per the following models:

US Filter J-Spin Decanter Centrifuge Models:

- CD26-432

- CD31-432

- CD37-432

- CD45-432

- CD51-432

- CD54-432

- CD58-432

- CD66-432

- CD76-402

Siemens CentraMax Decanter Centrifuge Models:

- CD26-432

- CD31-432

- CD37-432

- CD45-432

- CD51-432

- CD54-432

- CD58-432

- CD66-432

- CD76-402

Siemens CentraPac Decanter Centrifuge Package System Models:

- CP26-432

- CP31-432

- CP37-432

- CP45-432

- CP51-432

- CP54-432

- CP58-432

- CP66-432

- CP76

Hiller DR Model Decanter Centrifuge Models:

- DR26-432

- DR31-432

- DR37-432

- DR45-432

- DR51-432

- DR54-432

- DR58-432

- DR66-432

- DR76-402

KHD Standard Dewatering Decanter Centrifuges Models

- S 0-1

- S 1-1

- S 1-11

- S 2-1

- S 2-11

- S 3-0

- S 3-01

- S 3-02

- S 3-03

KHD Special Dewatering Decanter Centrifuges Models

- S 2-1 C

- S 2-1 G

- S 3-0 G

KHD Standard Thickening Decanter Centrifuges Models

- BS 1-11

- BS 2-11

- BS 3-01

- BS 3-02

- BS 3-03

- B 3-0

- B3-03

KHD 3-Phase Decanter Centrifuges Models

- S 2-1 PH

- S 3-01 PH

- PH530x1590

KHD High Dewatering Decanter Centrifuges Models

- CP 1-1.1

- CP 2-1.1

- CP 3-0.1

- CP 3-02.1

KHD / BIRD Humboldt / Baker Process High Dewatering Decanter Centrifuges Models

- CP 3034

- CP 3044

- CP 3054

Note: Machines were sold until 1997 as KHD or HDI (Humboldt Decanter Inc.) brands then as BIRD Humboldt for one year or two, and then as Baker Process. Some machines for the U.S. market from 1998 till 2000 were built in the U.S. with slightly different design, marked as SDC or BF types (SDC = small diameter centrifuges; BF = Blue Factory).