DRYCAKE TeknoMix+ Dynamic Inline Polymer Mixer

Langley Separation & Process now offers the innovative DRYCAKE TeknoMix+ series of inline Dynamic Polymer Mixers. The unique TeknoMix+ design results from many years of mechanical knowledge and process experience within the sludge treatment industry to develop a better method for injecting and mixing polymer into a sludge slurry to achieve optimum flocculation.

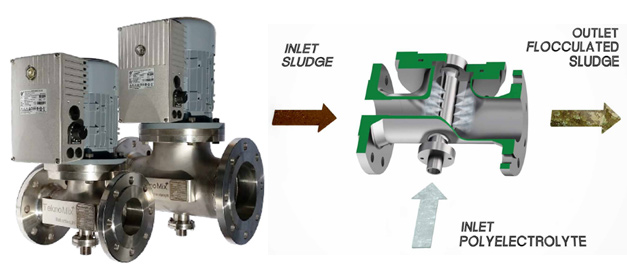

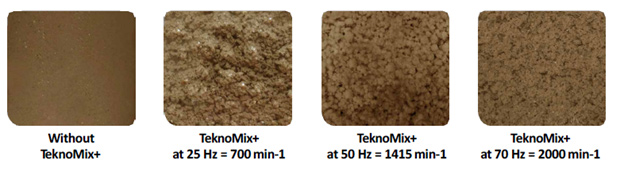

The TeknoMix Dynamic Polymer Mixer is an inline device for optimizing the injection and mixing of polymer into a sludge slurry stream. The TeknoMix Dynamic Polymer Mixer features an internal polyelectrolyte injection impeller that induces energy and turbulence to mix polymer and sludge slurry efficiently and effectively over a range of factors such as concentration, viscosity, and percentage of organics and colloids in the sludge. Thanks to the TeknoMix Dynamic Polymer Mixer’s adjustable impeller speed (RPM), it is possible to find the optimal energy and turbulence for each application. This allows an operator to control the flock formation and efficient release of the free water resulting in higher processing rates (due to the higher drainage speed) and dryer sludge cakes. Plus, more efficient injection and mixing means not a single drop of polyelectrolyte is wasted which reduces polymer consumption and saves money.

- Increase results in mechanical thickening, from 0.5% to 3% in dry solids.

- From 10% to 40% reduction in polymer dosage.

- Increase results in dewatering, from 1% to 5% in dry solids.

- Highly efficient even on difficult biological and/or very thick sludges.

- Easily adjustable RPM variation range to find the best mixing energy.

- Simple and easy installation, also within existing processes.

- Operator Friendly.

- Fast pay-back on an affordable investment cost.

Installation and Setup

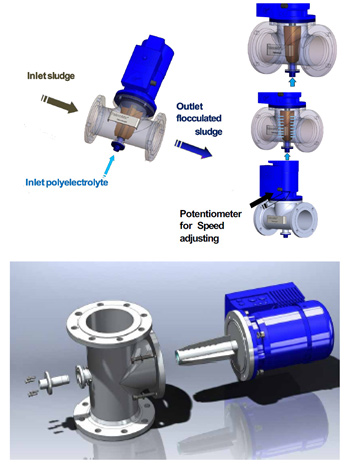

Installing a TeknoMix Dynamic Polymer Mixer into a thickening and/or dewatering equipment feed line is quick and easy. And the TeknoMix+’s compact design and flanged inlet outlet connections makes finding a suitable location for proper installation into existing feed piping relatively simple as well. The polymer injection point is already present on the TeknoMix+ and no other input fittings or connections are necessary.

The TeknoMix+ speed control is made via the Variable Frequency Drive integrated on to the electrical motor connection box. The internal injection impeller speed can be adjusted manually using the potentiometer directly fixed on the motor, or automatically via MODBUS protocol interfacing with remote PLC/SCADA.

DRYCAKE TeknoMix+ Models

- TM080 for flow rates up to 265-GPM

- TM125 for flow rates up to 440-GPM

- TM150 for flow rates up to 880-GPM

Langley Separation & Process can supply individual TeknoMix+ units or complete mix header solutions as well as providing installation and commissioning. Contact us for more information.